Metal components

Our product catalog contains stamped parts, fine blanking and gearboxes.

We offer our expertise to optimize our clients’ designs. Our machine park includes:

- Traditional automatic or manual presses from 60T to 800T

- Fine blanking presses from 80T to 630T

- Wire forming machines for diameters ranging from 2.5mm to 10mm

- Cathodic dip coating line

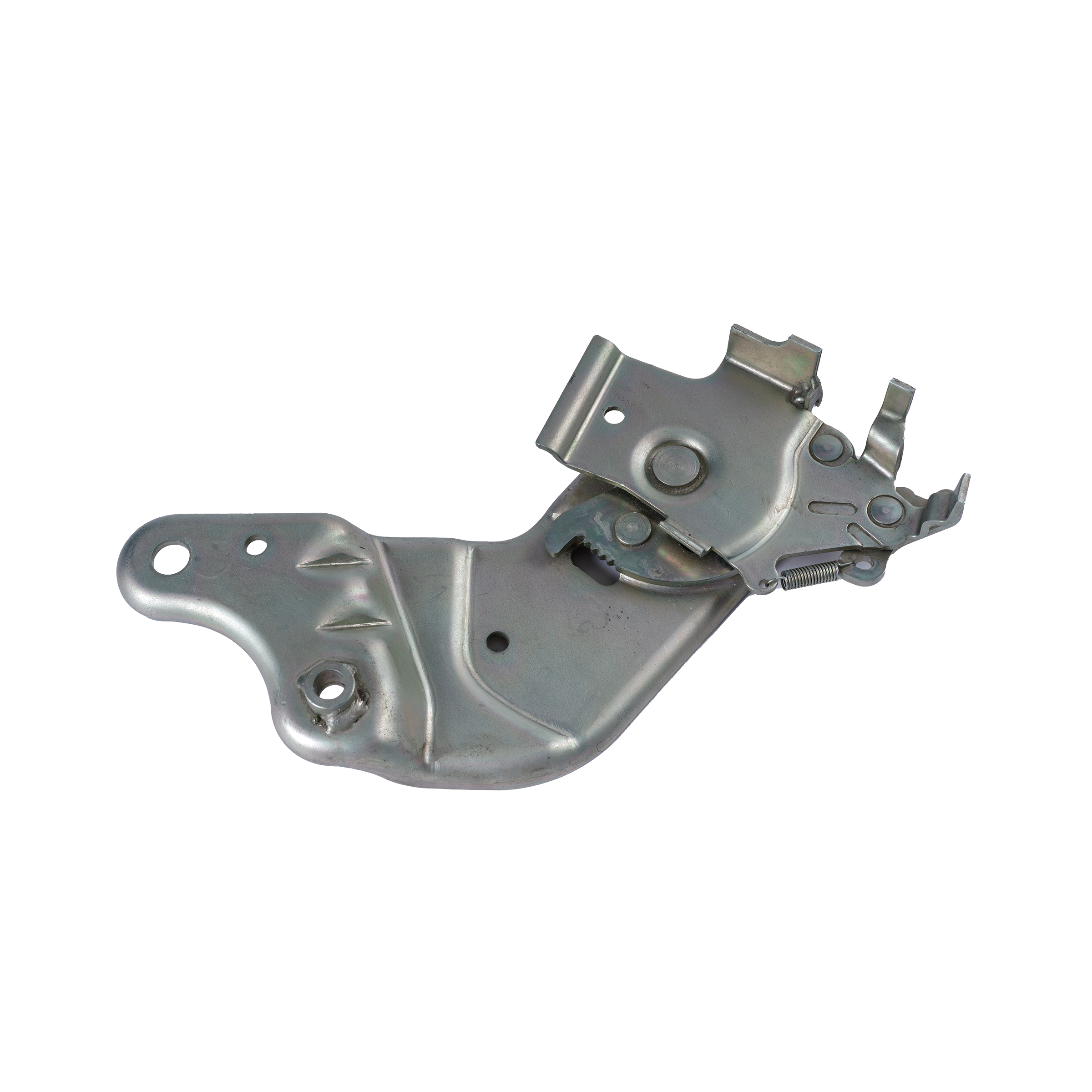

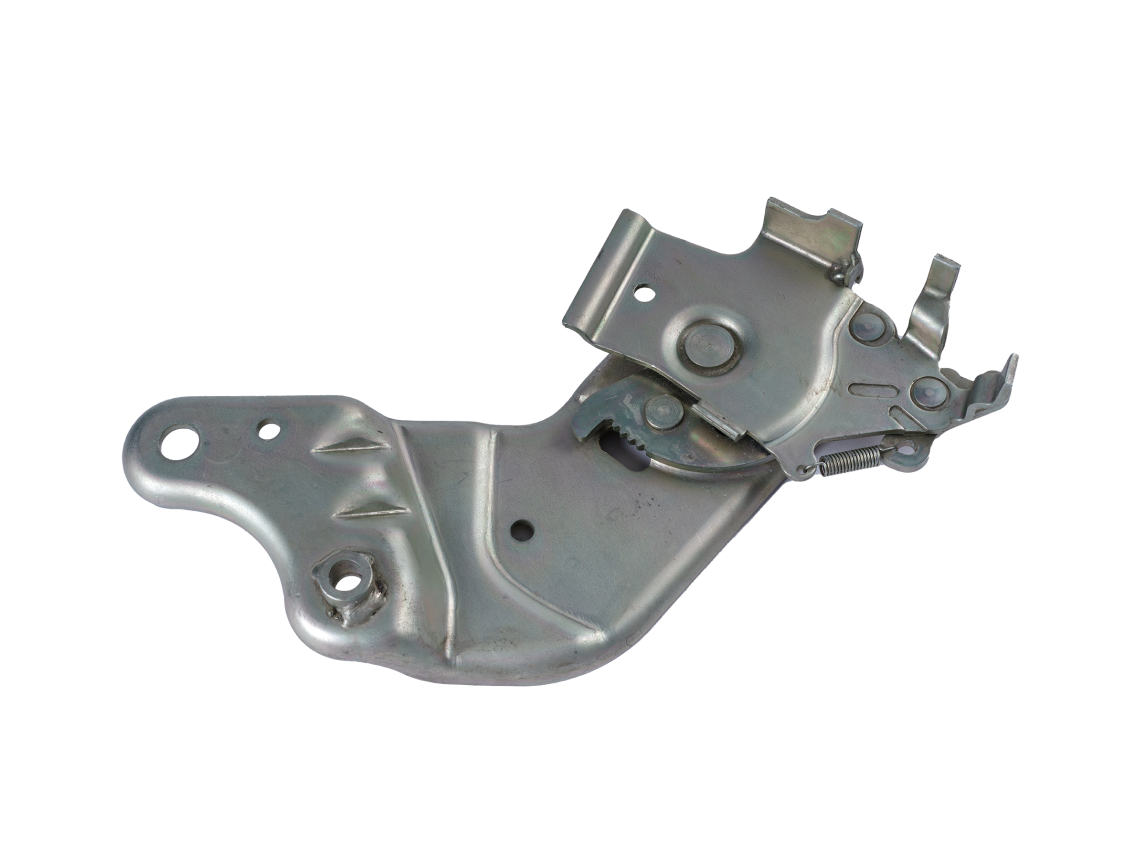

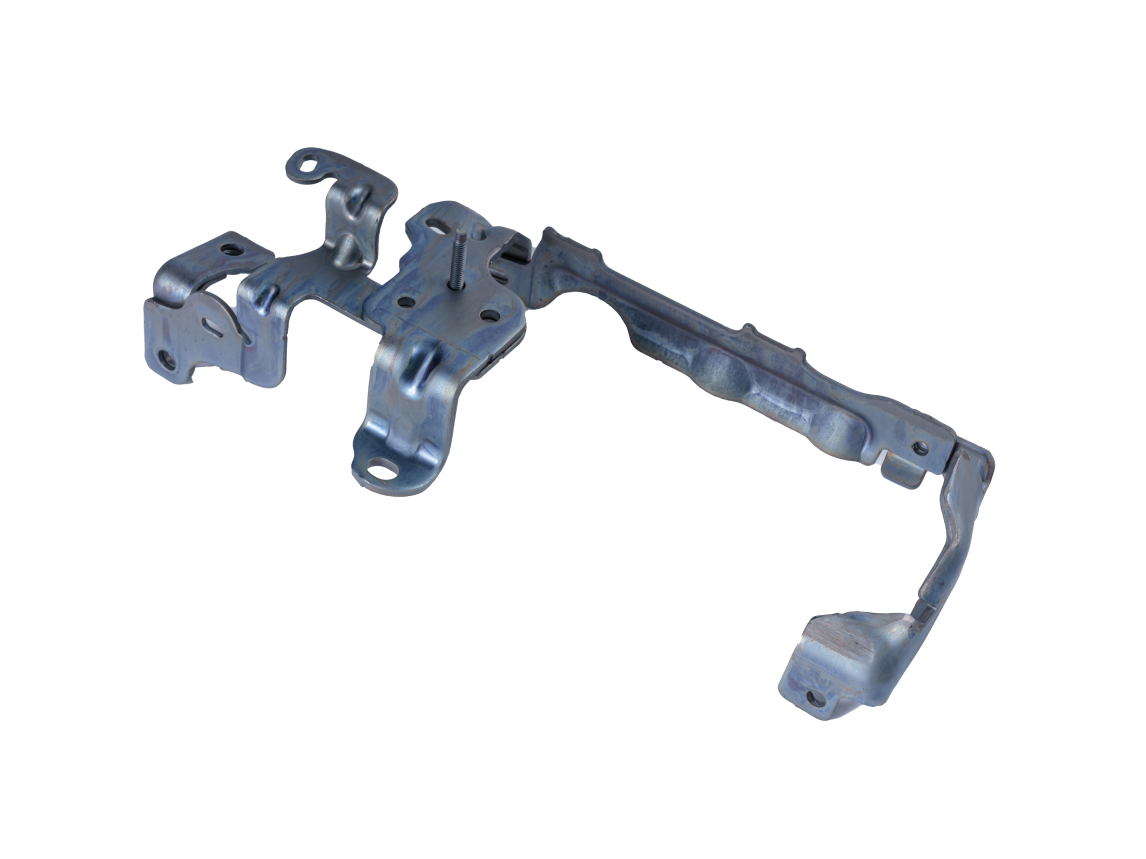

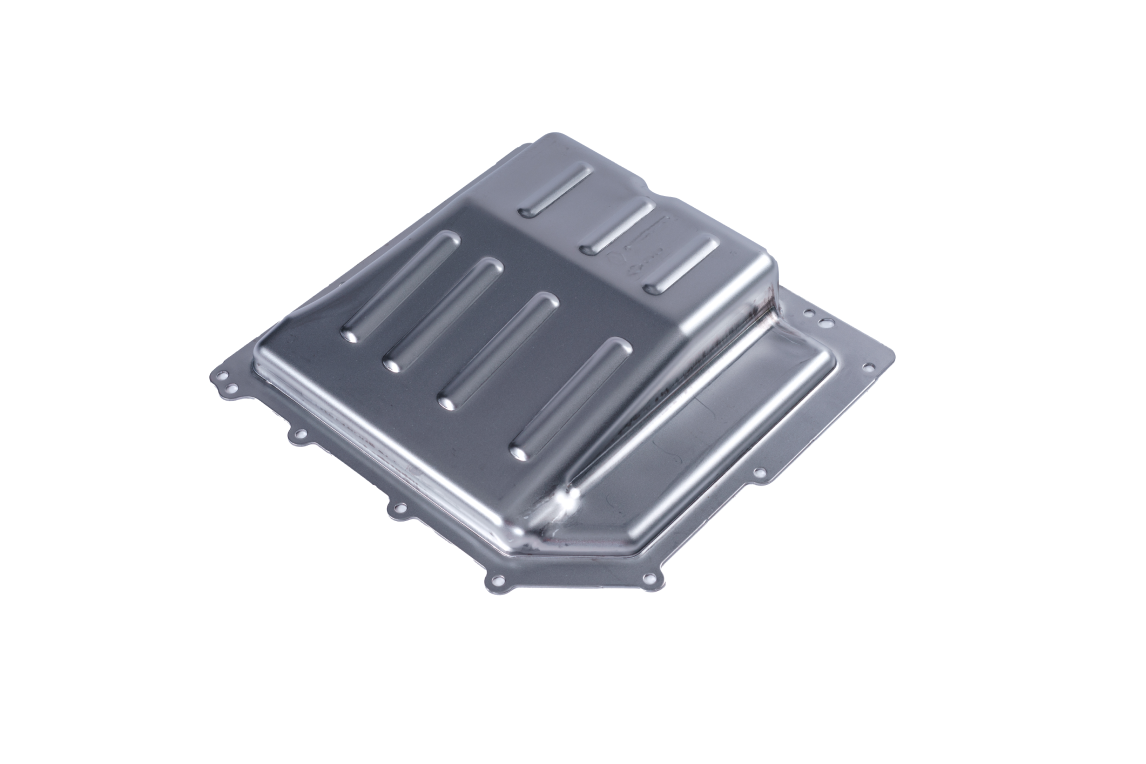

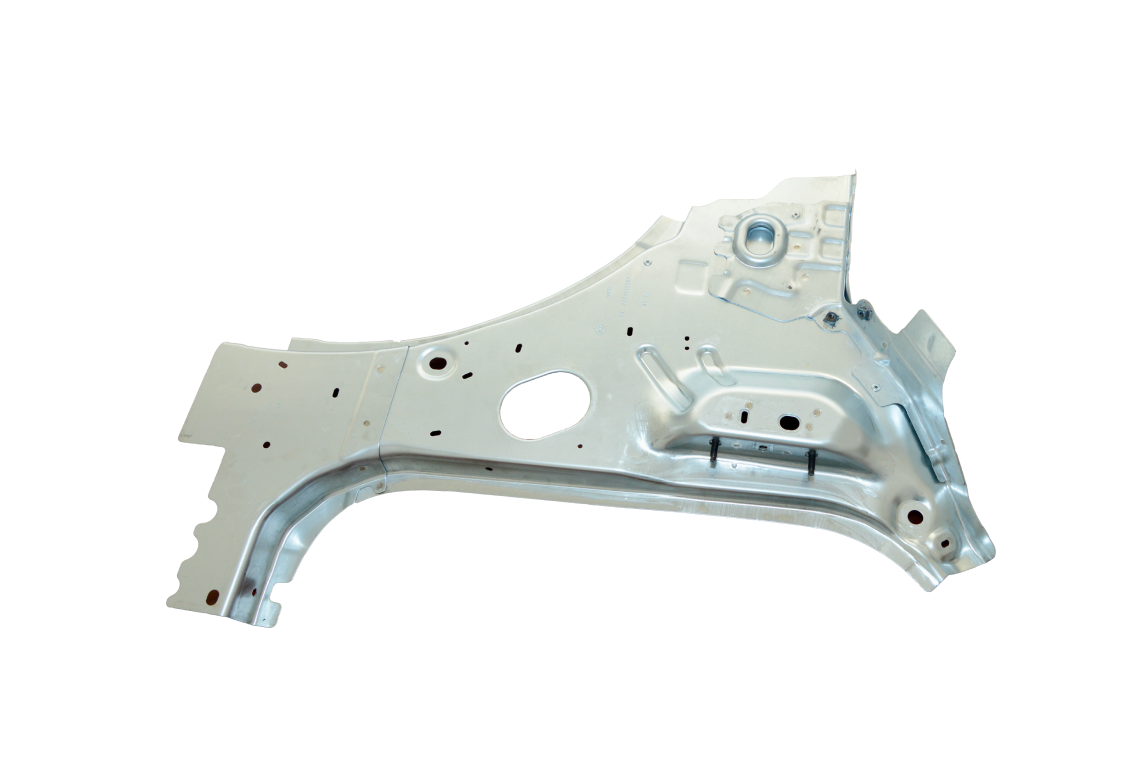

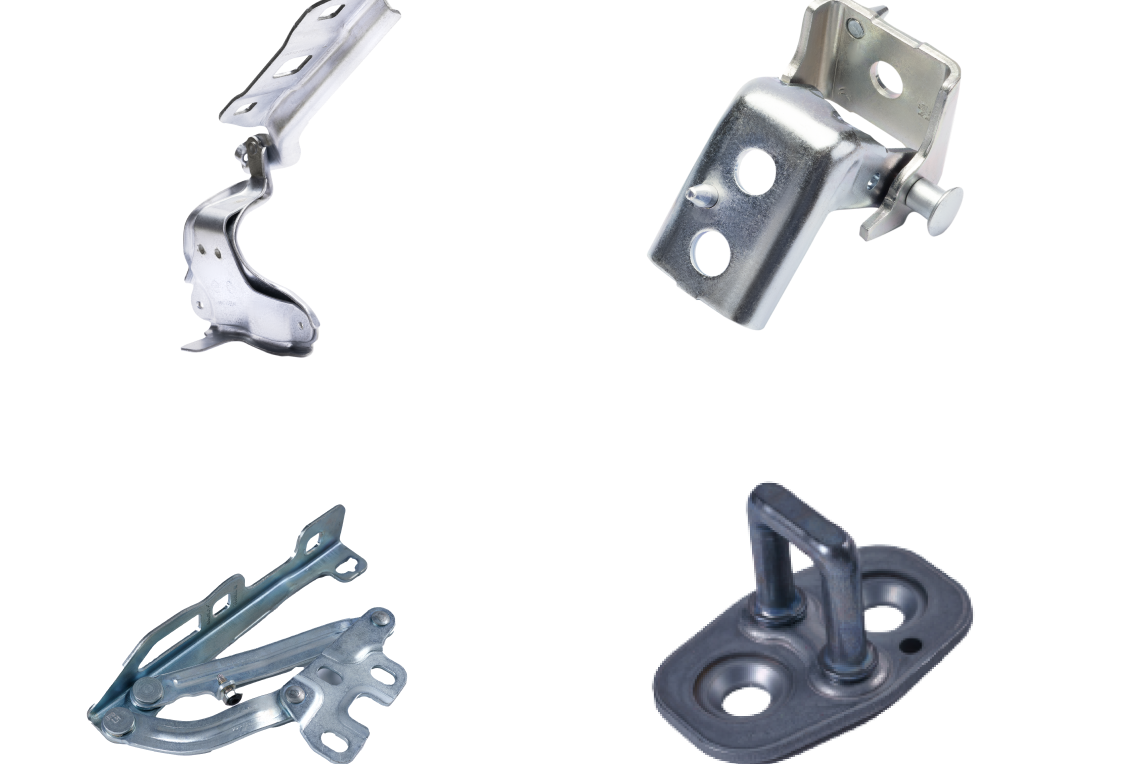

Traditional stamping

We manufacture diverse parts commonly used in the automotive environment, such as filter supports, low-power battery trays, thermal protectors, fastening brackets, calculator supports, pump supports, and more. These parts range from 30mm to 700mm in size, with thicknesses from 1mm to 4mm. They often undergo welding (sheet, nut, wire) and surface treatment operations. We design the parts in 3D to ensure functionality in highly constrained environments.

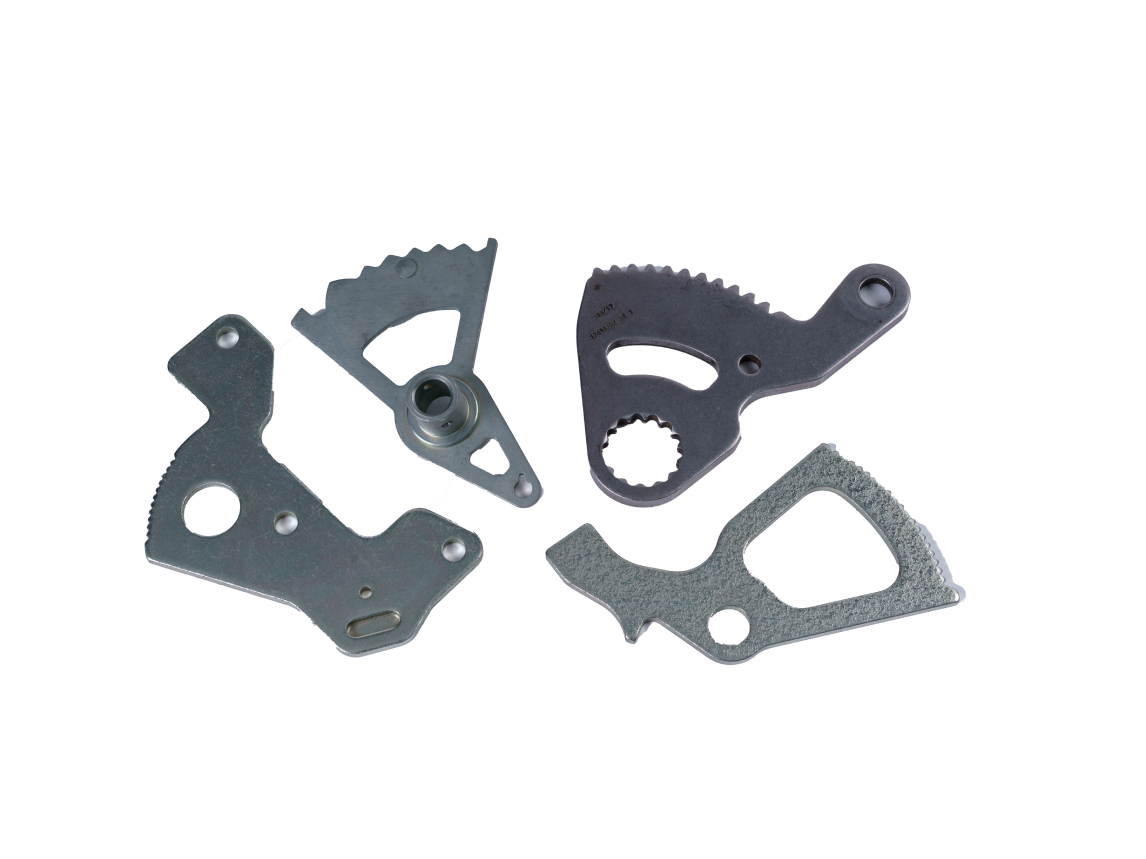

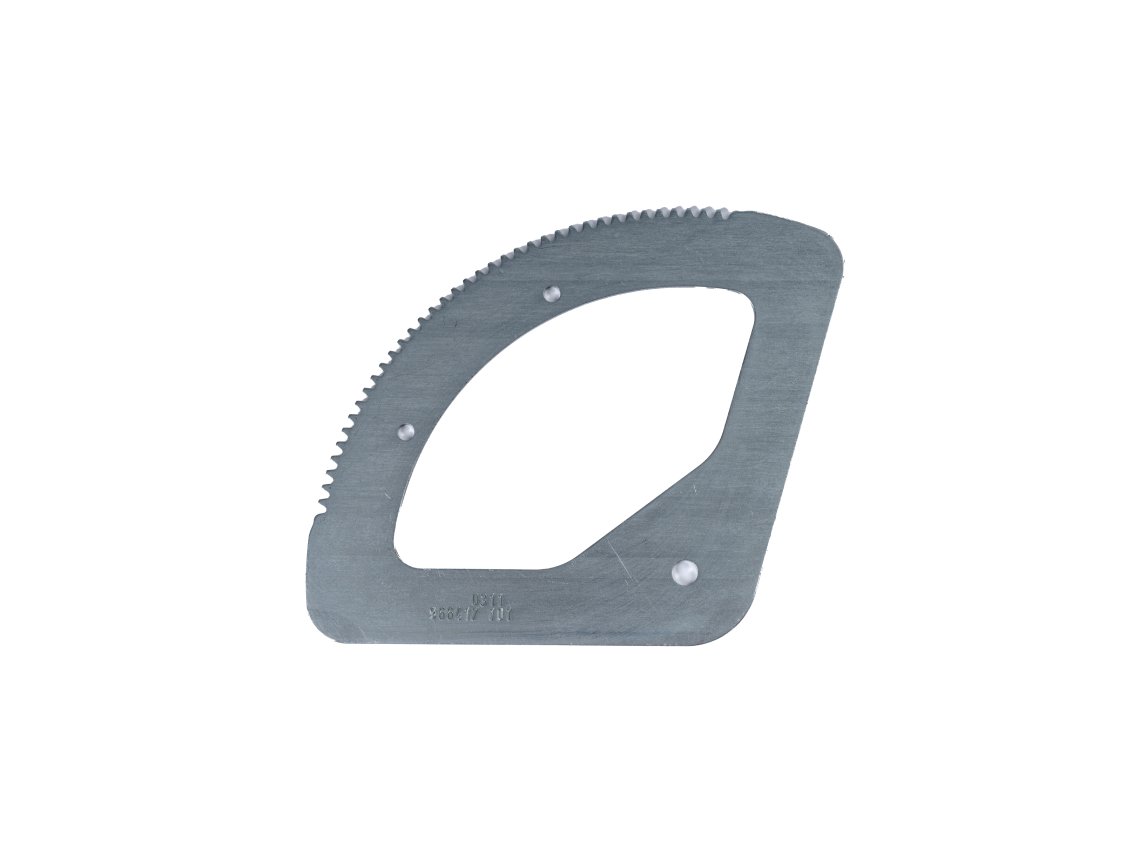

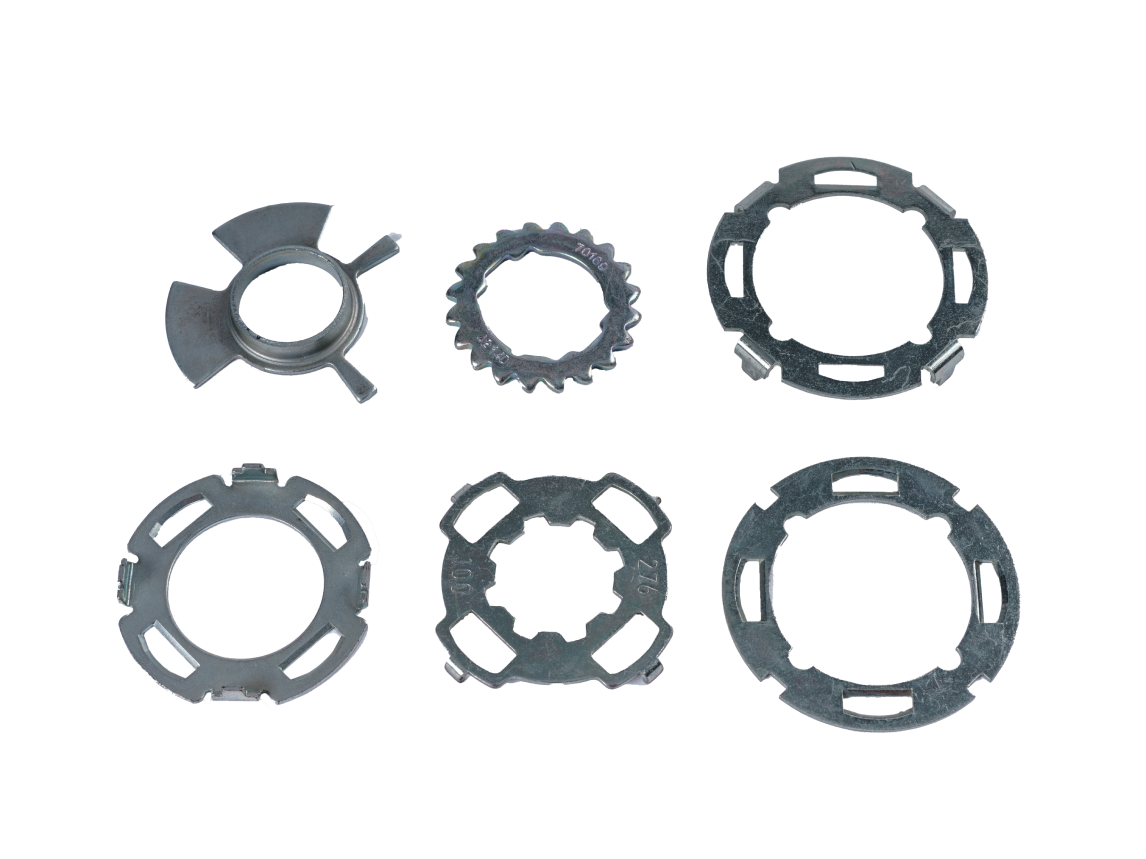

Fine Blanking

Through our specific process of precision cutting, fine blanking guarantees precise cuts with a clean edge quality from various thicknesses, ranging from low to high (up to 12mm). Optional finishing operations complement the possibilities: bending, machining, heat treatments, deburring, and more. Typical applications include locking mechanisms, seat components, hinges, gearbox components, reducers, parking brakes, and fastening elements.

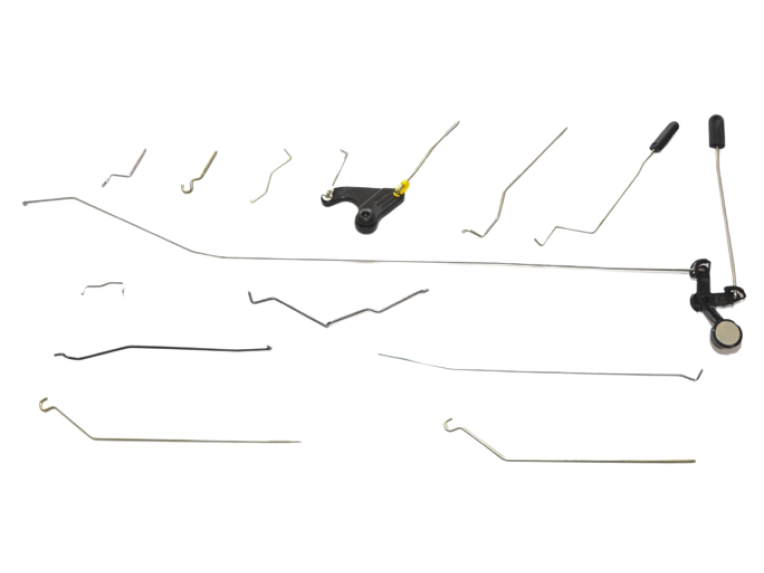

Wire forming

Defta shapes steel wires from 2.5mm to 10mm in diameter for door opening systems, hood props, latch wires, and reinforcement wires.

Ready to learn more?

Our team is here to assist you with any inquiries or information you may need.